About Bashan

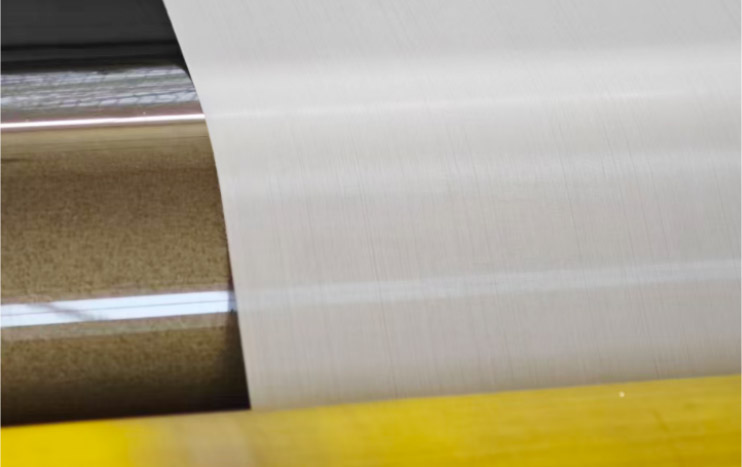

Original manufacturer of metal wire and metal wire mesh, with 70 years' of experience in metal wire drawing, woven wire mesh, and deep-processed wire mesh products.

Applications

Original manufacturer of metal wire and metal wire mesh, with 70 years' of experience in metal wire drawing, woven wire mesh, and deep-processed wire mesh products.

News

Learn more about our company news our latest developments.

R&D Capabilities

Original manufacturer of metal wire and metal wire mesh, with 70 years' of experience in metal wire drawing, woven wire mesh, and deep-processed wire mesh products.

Contact Us

We warmly welcome inquiries from partners worldwide.