Tang Slot Depth of Tang-Type Wire Thread Inserts: Details That Define Assembly Reliability

Tail inserts, with their cost-effectiveness and mature technology, have become the “unsung heroes” of high-precision manufacturing. From automotive transmission housings and EV battery trays to critical aerospace engine components, tail inserts are widely used. However, even mature technologies have critical details that determine assembly reliability—among them, the tang slot depth is a key parameter that should not be overlooked.

Why Tang Slot Depth Matters

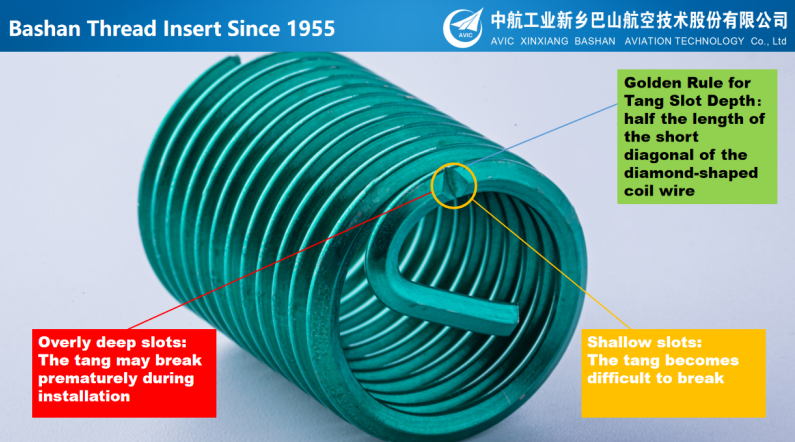

The tang of a tail insert is designed to facilitate installation. During insertion into a threaded hole, the tang should break cleanly after driving the insert into place, completing the assembly. If the slot depth is not properly controlled, two common problems can arise:

Overly deep slots: The tang may break prematurely during installation, causing the insert to fail to seat properly. This increases rework and scrap rates.

Shallow slots: The tang becomes difficult to break, leaving residual tang material after installation. This requires additional steps to remove or break the tang, reducing production efficiency and potentially affecting assembly accuracy.

In high-volume manufacturing, either scenario can lead to cost inefficiencies and quality risks. In sectors like automotive and aerospace, even minor deviations can result in assembly failures or reduced performance.

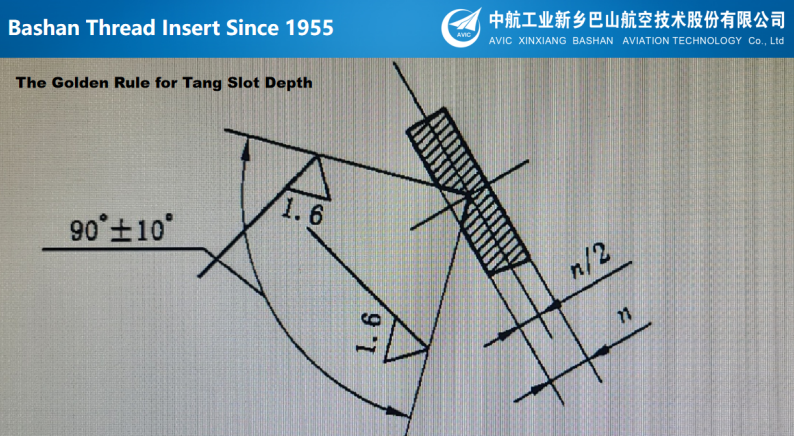

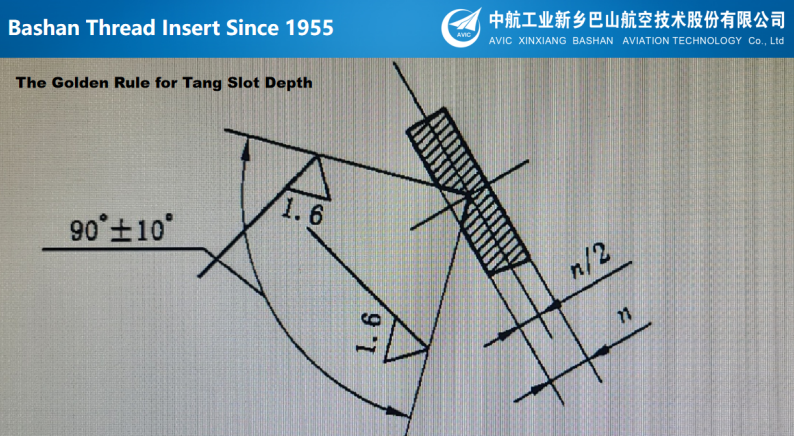

Best Practice: The Golden Rule for Tang Slot Depth

Through years of production experience and process optimization, we have found that setting the tang slot depth to half the length of the short diagonal of the diamond-shaped coil wire used to make the insert provides the optimal balance. This depth ensures the tang breaks cleanly during installation without premature failure or excessive resistance.

Specifically:

For high-strength stainless steel or nickel-based inserts, precise control of tang slot depth is critical. Automated inspection or vision measurement can help ensure consistency.

Standardizing slot depth across production batches minimizes tang breakage issues and residual tang problems, significantly improving assembly efficiency and product consistency.

The Value of Technical Optimization

Although tail insert technology is mature, careful control of tang slot depth demonstrates the importance of attention to detail in enhancing product reliability. For manufacturers, this reduces rework and scrap while strengthening customer confidence in the product.

For end customers—such as automotive transmission or aerospace engine manufacturers—this seemingly minor detail directly impacts assembly efficiency and reliability. In today’s high-precision and fast-growing industries like EVs and aerospace, focusing on these “small but critical” technical points is a key path to sustained competitiveness.

Conclusion

Tail inserts may be small, but they play a crucial role in assembly reliability. Precise control of tang slot depth is essential for smooth installation and risk reduction. Following the golden rule—setting the slot depth to half the short diagonal of the coil wire—helps manufacturers maintain consistency in mass production, improve efficiency, and ensure high-quality performance.

In high-end manufacturing, success often comes from the pursuit of perfection in details—and tang slot depth is one of those details that truly matters.