Sintered Wire Mesh

Custom solutions available upon customer request

Sintered Wire Mesh

Custom solutions available upon customer request

Product Overview

Product Overview Composed of multiple layers of woven wire mesh sintered in a vacuum furnace. It offers high mechanical strength, uniform pore distribution, and excellent backwash capability—suitable for high-temperature, high-pressure, and corrosive applications.

Product Parameters

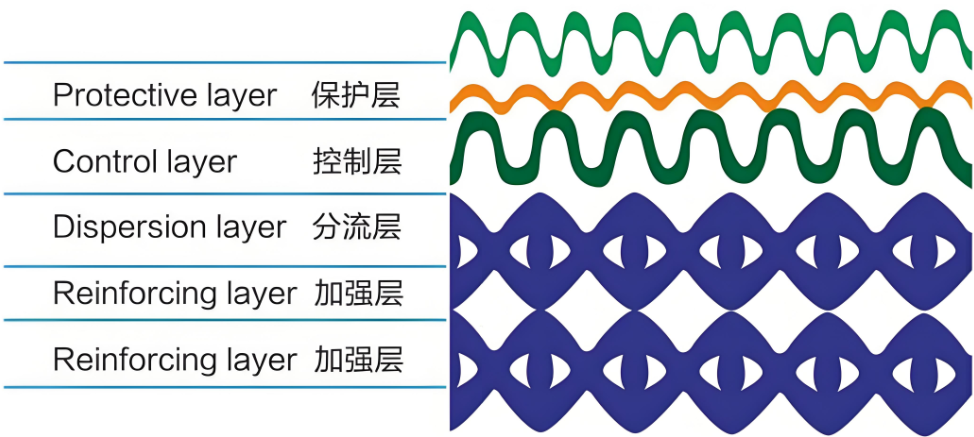

Product Parameters Standard Five-Layer Sintered Mesh Structure Diagram:

Sintered Plate Mesh

Sintered Plate Mesh is a high-performance composite filtration material, made by layering, pressing, and vacuum high-temperature sintering multiple layers of stainless steel wire mesh.Sintered Plate Mesh is a high-performance composite filtration material, made by layering, pressing, and vacuum high-temperature sintering multiple layers of stainless steel wire mesh.This material offers high strength, high-temperature resistance, corrosion resistance, and easy regeneration, effectively capturing fine particles, and is widely used in harsh filtration environments such as petrochemicals, polymer materials, and high-temperature flue gas.

Sintered Filtration Materials and Filter Production Process

Strong Sintered Core·Precision Filtration Performance

Please feel free to email us:arvin540@foxmail.com

Recommended Applications

Recommended Applications Metal sintered mesh is manufactured by stacking, pressing, and vacuum sintering multiple layers of metal wire mesh. It features high strength, stable aperture, high permeability, and washable/reusable properties, making it an ideal filtration material for demanding conditions, particularly where high precision, reliability, and long-term stability are required.

Recommended Application Areas:

01. Aerospace and Energy Equipment

Used in critical areas such as hydraulic system filtration, fuel filtration, and propulsion system filtration, ensuring stable and reliable operation.

02、Petrochemical and Chemical Processes

Suitable for catalyst recovery, polymer filtration, reactor vent filtration, and precision filtration of various high-pressure and high-temperature media.

03. Mechanical and Hydraulic Systems

Used for hydraulic oil and lubrication oil filter elements, capable of withstanding pressure pulses and mechanical shocks while maintaining long-term filtration accuracy.

04、Pharmaceutical and Food Industries

Used for fine filtration in pharmaceutical production, gas purification, and fermentation systems, offering high cleanliness and the ability to be repeatedly cleaned and regenerated.

05. Gas Distribution and Fluidized Beds

Used as gas distribution plates and fluidizing plates, providing uniform distribution and stable permeability, suitable for powder processing and reaction systems.

06. High-Temperature and Corrosive Environments

Suitable for filtration of various acidic and alkaline media, flue gas, thermal power, and nuclear power systems under harsh conditions.

Related Recommendations

Related Recommendations

Top

Follow us