Filter Elements

Custom solutions available upon customer request

Filter Elements

Custom solutions available upon customer request

Product Overview

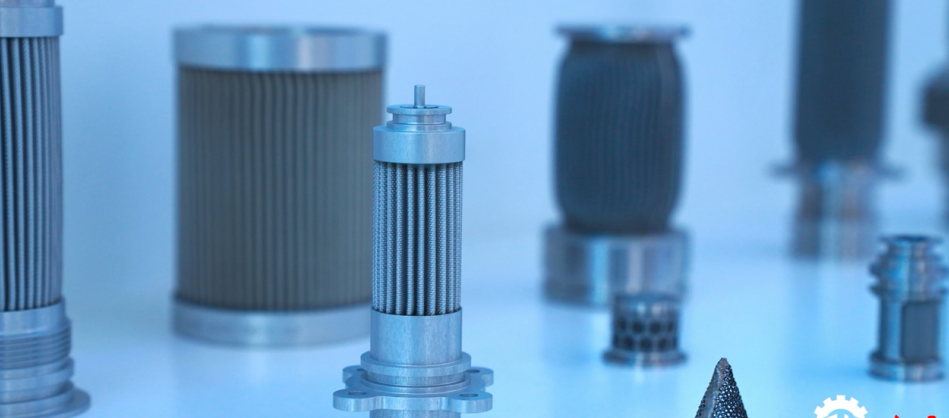

Product Overview Bashan manufactures a wide range of deep-processed filtration products, including pleated sintered mesh filters, powder-sintered filter elements, and wire-wound filter cartridges. These products are widely used in liquid and gas filtration across aerospace, automotive, marine, and chemical equipment applications. They offer excellent corrosion resistance, high-temperature stability, and high-performance filtration.

For more than 70 years, we have continuously provided customers with stable, premium-quality, and highly valuable filtration meshes and deep-processed products for both air and liquid filtration needs.

Introduction to Filter Assemblies and Filter Cartridges:

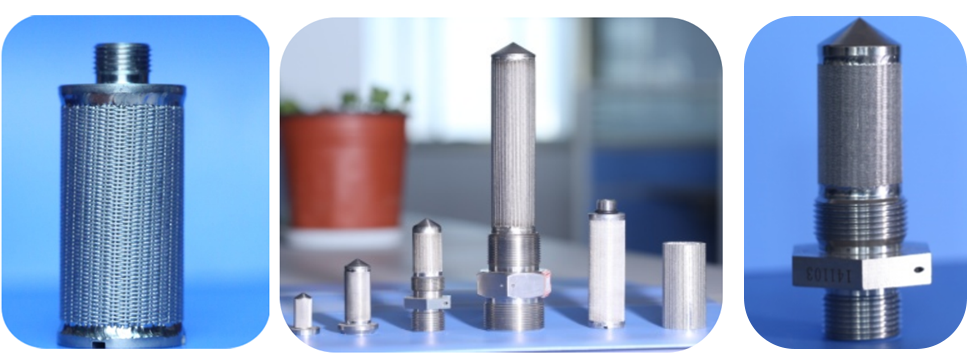

①Filter Assemblies

Filter assembly products are made by combining various specifications of filter mesh with other components. The main types include flat, disc, cylindrical, conical, and rectangular configurations.

②Sintered Plate Mesh Filter Cartridges

Sintered plate mesh filter cartridges are made by laser cutting, rolling, and welding multiple layers of sintered metal mesh. They feature high strength, stable aperture, high-temperature resistance, and excellent pressure-bearing capacity. With a robust structure and stable flow rate, these cartridges are washable and reusable, making them an ideal choice for long-term use in precision filtration applications.

Key Technical Parameters:

Operating Media: Liquid hydrogen, liquid oxygen, liquid nitrogen, hydraulic oil, compressed air, etc.

Media Temperature: -252°C to +450°C

Filter Material: Stainless Steel 304, 316L

Dimensions: Minimum inner diameter φ3 mm

Filtration Accuracy: 3–500 μm

Pressure Resistance: Up to 35 MPa

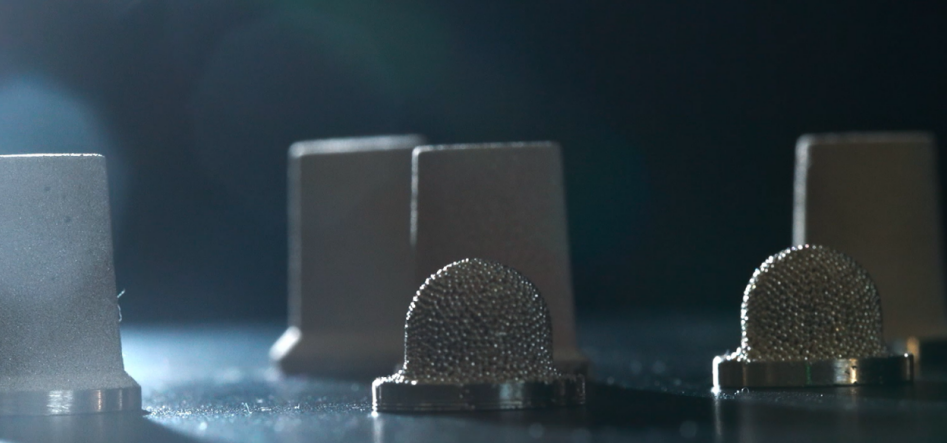

③Powder-Sintered Filter Cartridges

Powder-sintered filter cartridges are made by cold pressing metal powders followed by high-temperature sintering, forming a uniform and stable three-dimensional porous structure. They feature high porosity, excellent mechanical strength, precise and controllable filtration accuracy, and outstanding corrosion and high-temperature resistance. With uniform pore distribution and strong dirt-holding capacity, these cartridges can operate stably under high pressure, high temperature, and corrosive media for extended periods.

They are widely used in petrochemical plants, gas purification systems, pharmaceutical and food processing, instrument gas treatment, gas distribution and flow control, pyrotechnics and powder spraying processes, hydrogen energy, and new material equipment, making them an ideal choice for high-precision filtration, gas flow stabilization, and safety protection applications.

Filter Material: Tin bronze powder, stainless steel powder, high-temperature alloy powder, etc.

Dimensions: Minimum φ2 mm × 1 mm

Filtration Accuracy: 1 – 60 μm

Pressure Resistance: Up to 3 MPa

④Pleated Filter Cartridges

Common types of pleated filter cartridges include metal mesh pleated cartridges, metal felt pleated cartridges, fiberglass pleated cartridges, and filter paper pleated cartridges.

Key Technical Parameters:

Operating Temperature: -55°C to +225°C

Operating Pressure: 0–32 MPa

Filtration Accuracy: 0.1–500 μm

Product Parameters

Product Parameters Filter Cartridge Types and Application Scenarios:

| Pleated Wave Filter | Commonly used in fields such as hydraulics and water treatment to increase the filtration area. |

| Sintered Mesh Filter | Formed by sintering metal powder, it has high filtration precision and is suitable for precision filtration scenarios. |

| Powder Sintered Filter | Formed by sintering metal powder, it has high filtration precision and is suitable for precision filtration scenarios. |

| Monofilament Wound Filter | Made by winding metal wires, it is often used for oil filtration. |

Technical Parameters of Filtration Components:

| Operating Media | Liquid hydrogen, liquid oxygen, liquid nitrogen, hydraulic oil, compressed air, etc. |

| Media Temperature | -252℃~+450℃ |

| Filter Material | Stainless Steel 304、316L |

| Dimensions | Inner diameter as small as 3 mm |

| Filtration Accuracy | 1~500μm |

| Pressure Resistance | 0-35MPa |

Sintered Filtration Materials and Filter Production Process

Strong Sintered Core·Precision Filtration Performance

Please feel free to email us:arvin540@foxmail.com

Recommended Applications

Recommended Applications Different types of filter cartridges are suited to different applications:

Filter assemblies come in various configurations.

Sintered plate mesh cartridges are resistant to high temperature and high pressure, reusable, and ideal for precision filtration.

Powder-sintered cartridges provide precise filtration, corrosion and high-temperature resistance, and are widely used in petrochemical, pharmaceutical, and other industries.

Pleated cartridges come in diverse types, meeting a range of temperature, pressure, and filtration accuracy requirements.

Related Recommendations

Related Recommendations

Top

Follow us