Square wire Mesh

Custom solutions available upon customer request

Square wire Mesh

Custom solutions available upon customer request

Product Overview

Product Overview Bashan offers square wire meshes in a variety of materials, including stainless steel, copper, and nickel. Plain square meshes can be woven up to 640 mesh, while twill square meshes can reach up to 635 mesh, meeting diverse requirements from precision filtration to industrial classification. As a drafting organization of the national standard GB/T 5330, Bashan possesses extensive technical expertise and authoritative experience in the field of square wire mesh. Our products are widely used in filtration, screening, shielding, and other high-end industrial applications.

01 Stainless Steel Wire Mesh

Bashan provides a full range of stainless steel woven meshes widely used in air and liquid filtration, structural support, electrostatic discharge, screening, and various filtration applications. Our products are available in rolls, cut-to-size sheets, and precision-formed components. Standard roll length is 30 meters (customizable), and the minimum slitting width can reach 25 mm. Stainless steel woven mesh offers excellent corrosion resistance, temperature stability, and mechanical strength, making it one of the most commonly used industrial mesh materials for demanding operating conditions.

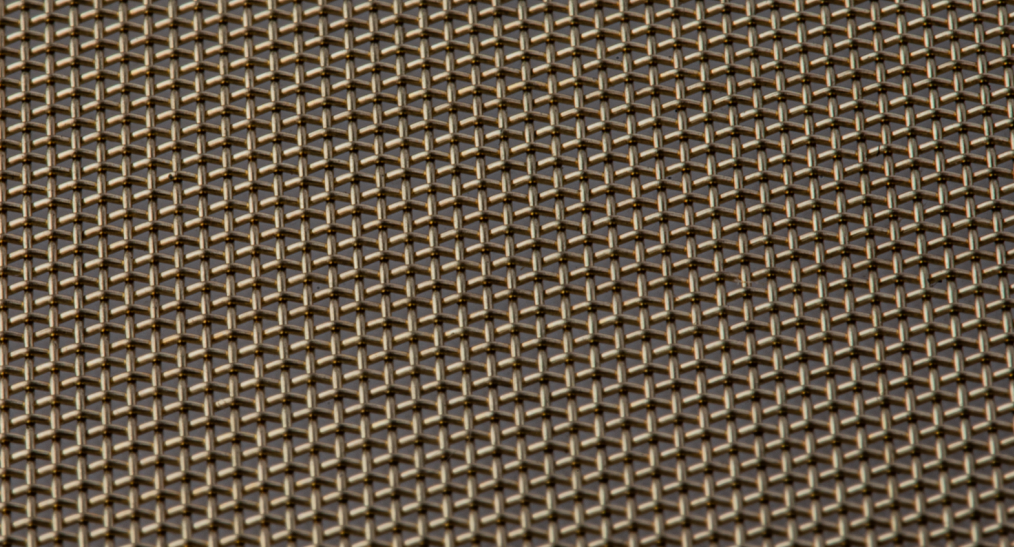

02 Copper Wire Mesh

Bashan’s copper meshes offer excellent electrical conductivity, thermal conductivity, ductility, and corrosion resistance, making them ideal materials for industries such as electronic shielding, propellant screening, marine engineering, and fluid filtration. They are widely used in RFI/EMI shielding, propellant sieving, grounding protection, marine protection, electronic components, and fluid filtration.

Available grades include:

Brass: Combines corrosion resistance with decorative appearance.

Phosphor Bronze: High strength, wear resistance, and fatigue resistance; suitable for electrical connectors and precision meshes.

Tin Bronze: Outstanding corrosion and impact resistance in marine and harsh environments.

03 Nickel Wire Mesh

Bashan offers a range of high-purity nickel meshes (N6, N4) and nickel alloy meshes (N200, Monel 400, etc.) designed for filtration, screening, and electrochemical applications in highly corrosive, high-temperature, high-purity, and strong reducing/oxidizing environments. These products are widely used in the chemical industry, batteries, hydrogen energy systems, fine metallurgy, and electronic gas filtration.

Key Properties & Features:

N6 Nickel Mesh (Nickel 200):Ultra-low carbon content with excellent corrosion resistance, especially suitable for aggressive chemical media and high-purity environments. Commonly used in hydrogen separation, water electrolysis (hydrogen production), and the chlor-alkali industry.

N4 High-Purity Nickel Mesh:Higher purity (≥99.98%), ideal for semiconductor processes, electronic gas filtration, and high-purity system applications.

Monel 400 Copper-Nickel Alloy Mesh:Offers strong mechanical properties and outstanding resistance to chloride corrosion, suitable for seawater treatment and marine corrosion-protection filtration.

Product Parameters

Product Parameters | Weave Type | Mesh Range | Aperture Range | Wire Diameter Range | Example Specifications |

| Plain Weave | 4目 ~ 640目 | 5 mm ~ 0.031mm | 1.0 mm ~ 0.009mm | e.g. 4 mesh (5 mm aperture,Ø1.0 mm wire Dia. ) 640 mesh ( 0.031mm aperture,Ø0.009 mm wire Dia.) |

| Twill Weave | 254目 ~ 635目 | 0.06 mm ~ 0.02mm | 0.04 mm ~ 0.02mm | e.g. 254 mesh (0.06 mm aperture,Ø0.04 mm wire Dia. ) 635 mesh (0.02 mm aperture,Ø0.02 mm wire Dia. ) |

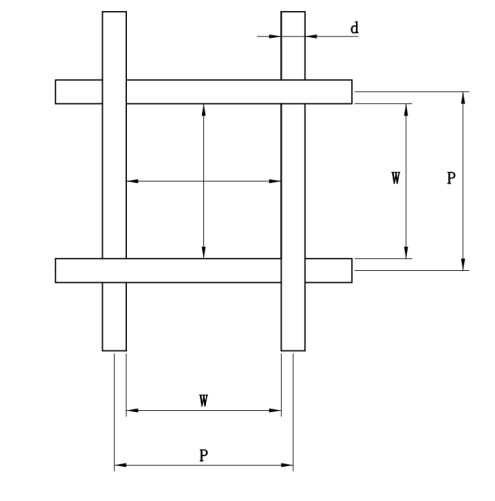

Aperture width (w)

The aperture width is the clear distance between two adjacent warp or weft wires.

Wire diameter (d)

The wire diameter refers to the thickness of the individual wires used in the woven mesh. Please note that the actual diameter may vary slightly due to the weaving process.

Pitch (p)

Pitch is defined as the center-to-center distance between two adjacent wires. It represents the sum of the aperture width (w) and the wire diameter (d):

p = w + d

Mesh count (n)

The mesh count indicates the number of apertures present along a specified linear unit, measured in a row, one behind the other. When measured over a length of 25.4 mm (1 inch), the mesh count is referred to simply as “Mesh”.

Mesh = number of apertures per linear inch = 25.4 mm ÷ pitch (p)

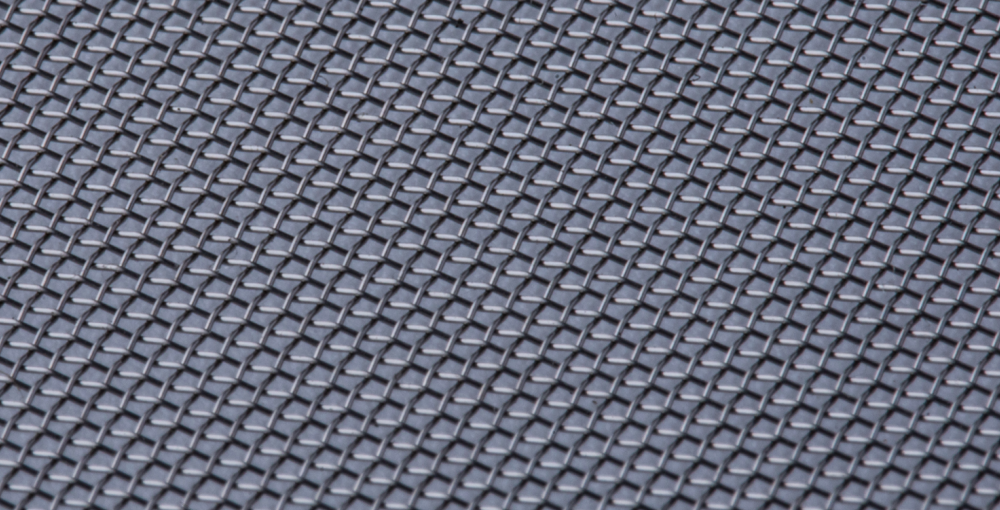

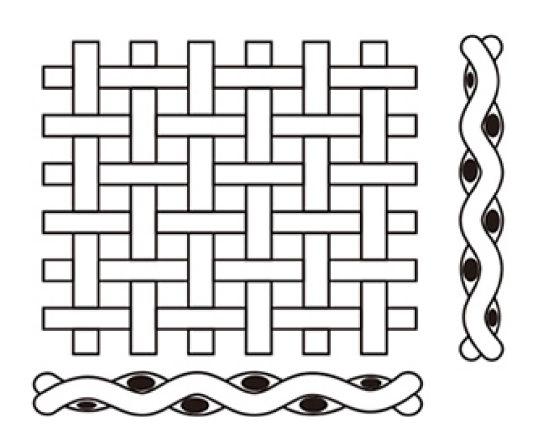

Plain Weave

In terms of plain weave, the warp and weft wires interlace alternately over and under each other. Both sides of the wire mesh show the same appearance.In this mesh structure, the wires are woven with gaps, forming open apertures through which solid particles and liquids can flow. The mesh features two significant characteristics: extremely low resistance during screening and filtration, and particularly excellent backwashing performance.

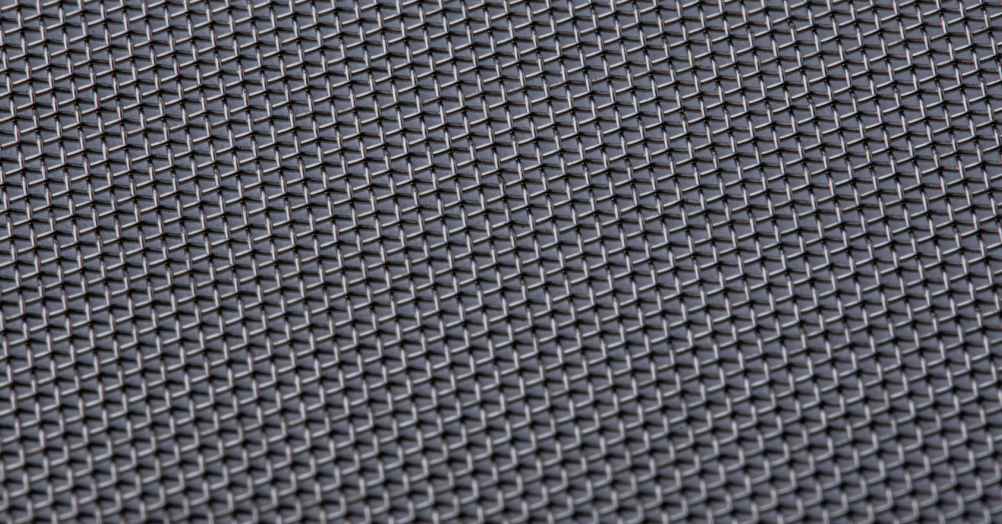

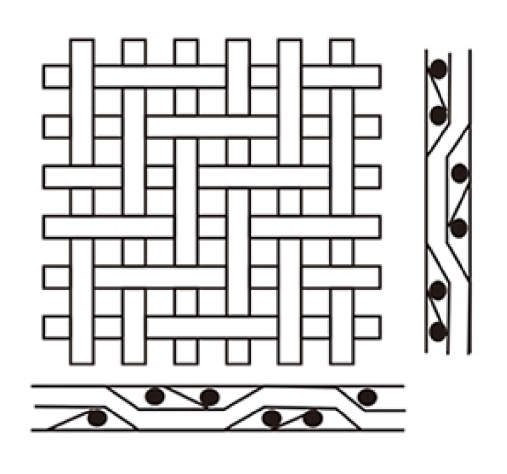

Twilled Weave:

The twill weave mesh features a 2/2 interlacing pattern, where each warp wire passes over and under two weft wires, and vice versa. This diagonal floating structure creates a distinctive twill pattern. Under identical wire diameter conditions, twill weave achieves greater density and tighter openings, leading to enhanced strength and filtration precision compared to plain weave.

Metal Mesh Production Process

Warping·Drawing-in·Weaving·Cleaning

Ultra-fine 640-mesh Plain Weave

Please feel free to email us:arvin540@foxmail.com

Recommended Applications

Recommended Applications Bashan offers a complete range of metal wire mesh specifications and materials, playing a vital role across numerous industrial and high-end manufacturing sectors. Our screens are widely used in the sieving of battery cathode and anode materials, metal powder classification, abrasives and grinding tools, propellant and fine chemicals screening, as well as high-purity processes such as alkaline water electrolysis for hydrogen production. With stable aperture accuracy, strict tolerance control, and a wide selection of alloy materials, Bashan meshes meet diverse requirements from ultra-fine powder screening to heavy-duty classification.

We understand that every industry and every customer has unique application needs. That’s why we are always ready to provide professional consultation and selection guidance tailored to your requirements—helping you improve screening efficiency, reduce operational costs, and enhance final product quality.

Related Recommendations

Related Recommendations

Top

Follow us