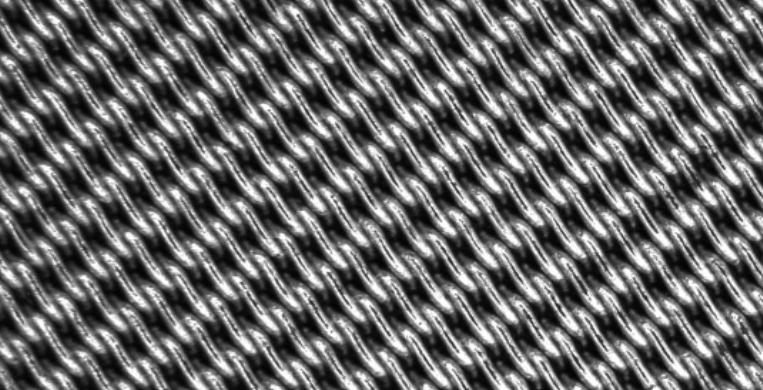

Dutch weave wire Mesh

Custom solutions available upon customer request

Dutch weave wire Mesh

Custom solutions available upon customer request

Product Overview

Product Overview Bashan offers Dutch weave meshes in a variety of materials, including stainless steel and nickel, designed to meet high-precision filtration and industrial deep-processing requirements. The meshes are available in multiple weave types, including plain Dutch weave, twill Dutch weave, and reverse weave, suitable for a wide range of filtration applications. As a drafting organization of the national standard GB/T 21648, Bashan possesses extensive technical expertise and authoritative experience in the Dutch weave mesh field. Our products are widely used in aerospace, energy, chemical, and high-precision filtration industries.

Product Parameters

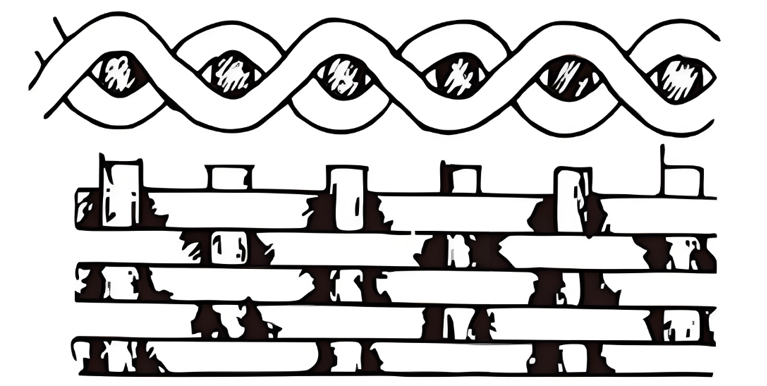

Product Parameters Plain Dutch Weave:

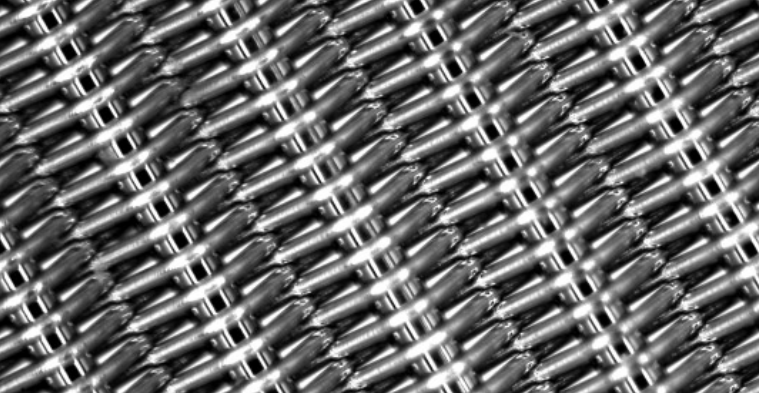

Plain Dutch Weave

Plain Dutch weave meshes feature a subtly ridged surface and are well~suited for applications requiring high flow capacity with minimal pressure drop. They are commonly employed in scenarios involving elevated mechanical loads, such as in sedimentation filters and filter candles.

| Weave Type | Mesh Range | Nominal aperture Size Range | Thickness Range | Weight Range kg/㎡ |

| Plain Dutch Weave | 118x740/0.063x0.036~7x40/0.90x0.71 | 23μm ~347μm | 0.135 mm ~ 2.32 mm | 0.38 mm ~ 6.65 mm |

Click to download the full specifications sheet:TECHNICAL DATA PLAIN DUTCH WEAVE (PDF)

Twill Dutch Weave:

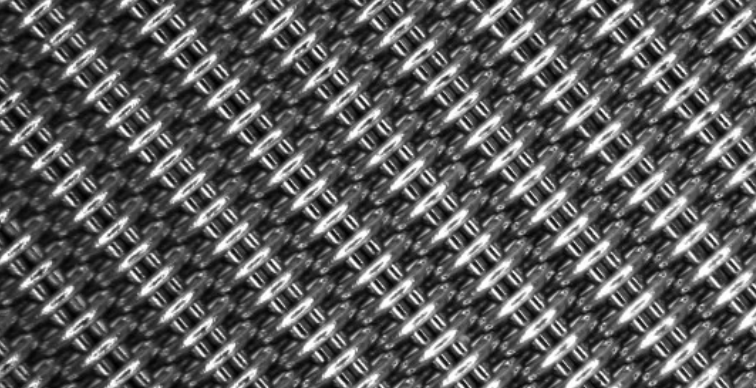

Twill Dutch Weave

Twill Dutch weave mesh is woven from monofilament wires and features extremely fine pore sizes with a smooth surface. The increased wire cross~section enhances the structural stability of the mesh. As fluid passes through the mesh layers, particles are forced to traverse staggered pore channels, enabling the effective retention of elongated, fibrous, or flat~shaped contaminants.

Fine~grade twill Dutch meshes are widely used in high~precision filtration applications, such as in lubricating oil and fuel filters. These meshes are typically made from high~grade stainless steel. Their slightly textured surface contributes to excellent flow characteristics and strong mechanical resistance, making them highly reliable under demanding operating conditions.

| Weave Type | Mesh Range | Nominal aperture Size Range | Thickness Range | Weight Range kg/㎡ |

| Twill Dutch Weave | 500x3500/0.025x0.015~20x260/0.25x0.2 | 3μm ~119μm | 0.055 mm ~ 0.65 mm | 0.3 ~ 3.14 |

Click to download the full specifications sheet:TECHNICAL DATA PLAIN DUTCH WEAVE (PDF)

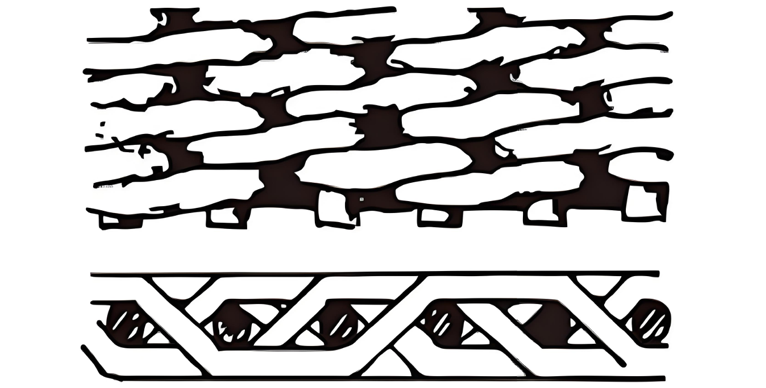

Metal Mesh Production Process

Warping·Drawing-in·Weaving·Cleaning

National Standard Setter for Dutch Weave Wire Mesh

Please feel free to email us:arvin540@foxmail.com

Recommended Applications

Recommended Applications

Plain Dutch Weave

Suitable for: Conditions requiring relatively high mechanical load and medium-precision filtration.

Typical Applications:

Sedimentation filters, cartridge filters

High-pressure solid-liquid separation

Petrochemical and fine chemical filtration

Catalyst recovery systems

Features:

Robust structure

High pressure resistance

Stable flow performance

Twill Dutch Weave

Twill Dutch Weave Fine Mesh

Used for: Critical systems requiring high filtration precision and high stability.

Fine Specifications Suitable For:

High-precision pressure filters in hydraulic control systems

Fuel filters for hazardous conditions

Precision filtration in aerospace and energy equipment

Protective filtration for instruments and meters

Coarse Specifications Suitable For:

Pressure/vacuum filters (plate, honeycomb, drum type)

Porous media in fluidized beds

Stable flow filtration of high-viscosity media

Features:

Smaller aperture sizes

Higher filtration precision

Broader range of applications

Industry-specific customization support

Each industry has unique operational requirements. Bashan can provide tailored solutions based on your filtration media, flow rate, pressure differential, and equipment needs, including:

Selection guidance

Customized apertures and materials

Complete filtration solutions

Helping you improve efficiency, reduce costs, and optimize product quality.

Related Recommendations

Related Recommendations

Top

Follow us