Stainless Steel Wire

Custom solutions available upon customer request

Stainless Steel Wire

Custom solutions available upon customer request

Product Overview

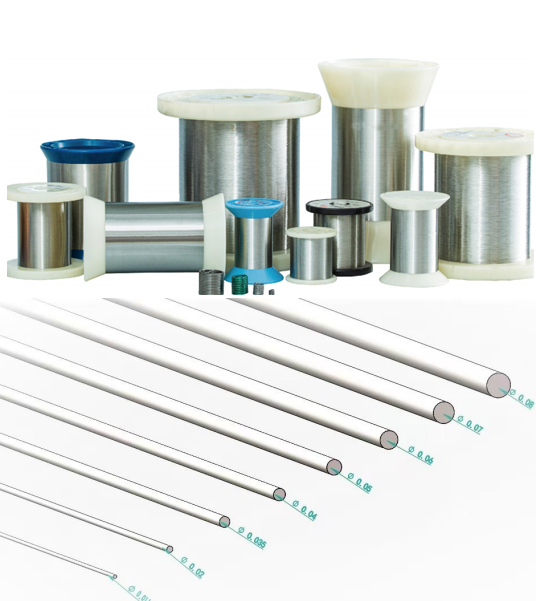

Product Overview Bashan stainless steel wire is produced with premium raw materials from UGITECH, Nippon Steel, and TISCO. The diameter range covers 0.011–5.0 mm, offering excellent corrosion resistance and mechanical properties. Applications include metal wire mesh, cut-resistant gloves, textile yarn, electronics, and precision parts. Customized grades, surface finishes, and mechanical properties are available upon request.

Product Parameters

Product Parameters | Chemical Composition % | ||||||||||

| ASTM/AISI(US) | DIN/EN | C | Mn | P | S | Si | Cr | Ni | Cu | Mo |

| 304 | 1.4301 | Max-0.08 | Max-2.00 | Max-0.045 | Max-0.030 | Max-1.00 | 18.00-20.00 | 8.00-10.50 | - | - |

| 304L | 1.4306 | Max-0.03 | Max-2.00 | Max-0.045 | Max-0.030 | Max-1.00 | 18.00-20.00 | 8.00-12.00 | - | - |

| 316 | 1.4401 | Max-0.08 | Max-2.00 | Max-0.045 | Max-0.030 | Max-1.00 | 16.00-18.00 | 10.00-14.00 | - | 2.00-3.00 |

| 316L | 1.4404 | Max-0.03 | Max-2.00 | Max-0.045 | Max-0.030 | Max-1.00 | 16.00-18.00 | 10.00-14.00 | - | 2.00-3.00 |

| 314 | 1.4841 | Max-0.25 | Max-2.00 | Max-0.045 | Max-0.030 | 1.50-3.00 | 23.00-26.00 | 19.00-22.00 | - | 2.00-3.00 |

| 310S | 1.4845 | Max-0.08 | Max-2.00 | Max-0.045 | Max-0.030 | Max-1.50 | 24.00-26.00 | 19.00-22.00 | - | - |

| 904L | 1.4539 | Max-0.02 | Max-2.00 | Max-0.045 | Max-0.035 | Max-1.00 | 19.00-23.00 | 23.00-28.00 | 1.00-2.00 | 4.00-5.00 |

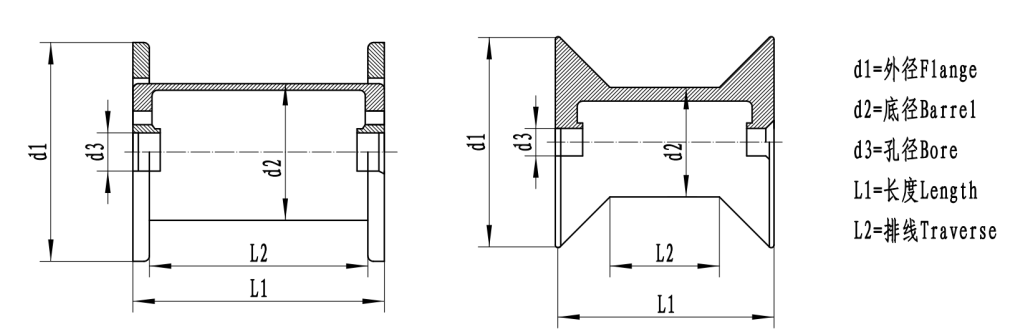

Spool Type Structure Diagram

| Wire diameter and Biconical spool | |||||||

| Model | Wire Dia. | d1 | d2 | d3 | L1 | L2 | Capacity Max. kg |

| HK63/45/16 | 0.015~0.018 | 63 | 44 | 16 | 85 | 60 | 0.3 |

| HK80/45/16 | 0.02~0.07 | 80 | 55 | 16 | 100 | 70 | 0.8 |

| HK80/45/20 | 0.02~0.07 | 80 | 55 | 20 | 100 | 70 | 0.8 |

| HK100/59-160 | 0.02~0.07 | 100 | 75 | 59 | 160 | 92 | 2 |

| HK100/25-160 | 0.02~0.07 | 100 | 75 | 25 | 160 | 92 | 2 |

| HK115 | 0.02~0.07 | 115 | 90 | 25 | 138 | 75 | 2 |

| Wire diameter and Cylindrical Barrelled Delivery | |||||||

| Model | Wire Dia. | d1 | d2 | d3 | L1 | L2 | Capacity Max. kg |

| DIN80-16 | 0.02~0.07 | 80 | 50 | 16 | 80 | 64 | 0.8 |

| DIN80-20 | 0.02~0.07 | 80 | 50 | 20 | 80 | 64 | 0.8 |

| DIN100 | 0.08~0.15 | 100 | 63 | 16 | 100 | 80 | 1.5 |

| DIN125 | 0.08~0.15 | 125 | 80 | 16 | 125 | 100 | 3 |

| DIN160 | 0.15~0.5 | 160 | 100 | 22 | 160 | 128 | 6 |

| DIN200 | 0.2~0.6 | 200 | 125 | 22 | 200 | 160 | 13 |

Metal Wire Production Process

Precision Drawing·Annealing·Excellence in Every Strand

Please feel free to email us:arvin540@foxmail.com

Stainless Steel Wire Diameter Deviation, Ovality Deviation, and Mechanical Properties

Stainless Steel Wire Diameter Deviation, Ovality Deviation, and Mechanical Properties

|

Wire Diameter Classification |

Wirediameter (d/mm) |

Diametertolerance (mm) |

Tensilestrength(N/mm²) |

Elongation≥ (%) |

|

| 304、304L | 316、316L | ||||

| Coarse Wire | 1.120~1.600 | ±0.015 | 650~800 | 600~750 | 35 |

| 0.710~1.000 | ±0.010 | 650~830 | 600~780 | 35 | |

| 0.450~0.630 | ±0.008 | 670~850 | 620~800 | 33 | |

| 0.280~0.400 | ±0.006 | 700~890 | 650~820 | 32 | |

| 0.20~0.250 | ±0.004 | 720~890 | 650~820 | 32 | |

| 0.112~0.160 | ±0.003 | 720~900 | 650~820 | 29 | |

| 0.09~0.100 | -0.002~+0.003 | 750~950 | 650~880 | 25 | |

| Wire Diameter Classification |

Wirediameter (d/mm) |

Diametertolerance (mm) |

Tensilestrength(N/mm²) |

Elongation≥ (%) |

|

| 304、304L | 316、316L | ||||

| Fine Wire | 0.071~0.08 | -0.002~+0.003 | 750~950 | 650~880 | 25 |

| 0.06 | -0.002~+0.003 | 750~950 | 660~880 | 24 | |

| 0.05 | ±0.002 | 750~950 | 660~880 | 24 | |

| 0.04 | ±0.002 | 750~1000 | 660~880 | 24 | |

| 0.035 | ±0.002 | 750~1000 | 660~880 | 24 | |

| 0.03 | ±0.002 | 750~1000 | 660~880 | 24 | |

| 0.025 | ±0.001 | 750~1000 | 660~880 | 24 | |

| 0.02 | ±0.001 | 750~1000 | 660~880 | 23 | |

| Ultra-fine Wire | 0.018 | ±0.001 | 1000~1300 | 700~900 | 22 |

| 0.015 | ±0.001 | 1000~1300 | 700~900 | 20 | |

Recommended Applications

Recommended Applications

Related Recommendations

Related Recommendations

Top

Follow us