Tangless wire thread insert

Custom solutions available upon customer request

Tangless wire thread insert

Custom solutions available upon customer request

Product Overview

Product Overview

Why Choose Tangless wire thread inserts?

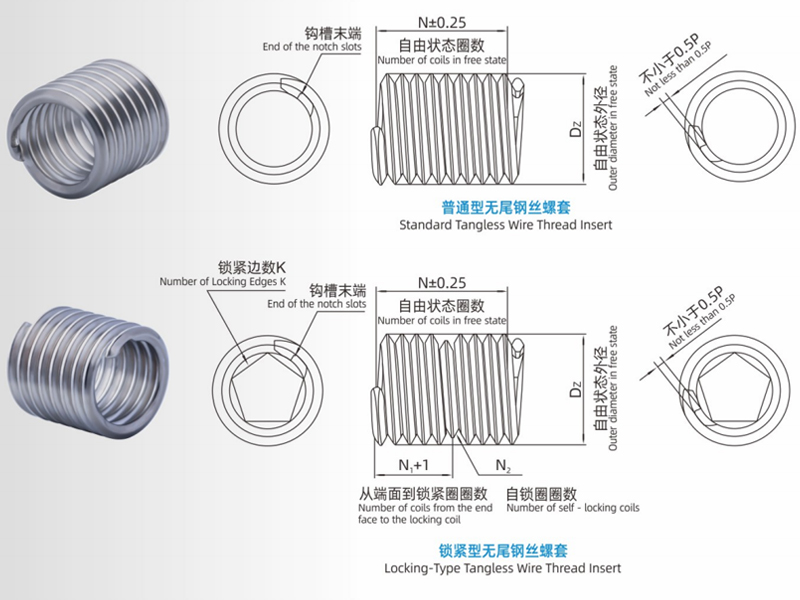

1.Tangless wire thread inserts feature notches at both ends, which means there is no tang that needs to be broken off, removed, or discarded.

2.The notch-slot design allows easy repositioning or removal of the insert if installed too deep, without causing damage to the parent threads.

3.No need for tang-break tools or for time-consuming removal of broken tangs in blind holes, saving both time and labor.

4.FOD-free installation with no debris or residue, enhancing the safety and reliability of automotive, electronics, and aerospace equipment.

5.The bi-directional notch-slot design allows installation without orientation, simplifying the process.

Tangless Helical Insert Installation Tools

Taps for Wire Thread Inserts

Taps for wire thread inserts are used to machine special internal threads for wire thread insert installation holes. They are manufactured according to the national standard GB3464-83 (Straight-shank machine and hand taps) and are made of W6Mo5Cr4V2 high-speed steel. They can be used for both machine and manual tapping.

Straight-Flute Taps

Straight-flute taps have a wide range of applications and can be used for both through-holes and blind holes, as well as for ferrous and non-ferrous metals. Suitable for both hand and machine tapping and are relatively inexpensive. However, they are less specialized — short-lead taps are used for blind holes, and long-lead taps are used for through-holes.

Spiral-Flute Taps

Spiral-flute taps are more suitable for blind holes, especially when used with dedicated tapping machines or machining centers. Chips are expelled backward during tapping, resulting in high cutting efficiency and good surface quality of the internal threads.

Forming (Roll) Taps

Forming taps are ideal for machining tough non-ferrous metals, especially copper, aluminum alloy castings, and stainless steel. They produce internal threads through cold-forming, which yields high tensile and shear strength and better surface roughness.

Wire Thread Insert Installation Wrenches

Manual Installation Wrench

The basic principle is to guide the insert through a lead thread that compresses its outer diameter, allowing smooth insertion into the base hole.

Automatic Installation Wrenches

Automatic installation wrenches come in pneumatic and electric versions, featuring high efficiency, speed, and accurate positioning. They are suitable for mass installation of wire thread inserts or for use on assembly production lines.

Thread Plug Gauges for Wire Thread Inserts

Used to check the internal threads of the base holes prepared for wire thread inserts.

Product Parameters

Product Parameters Tangless Wire Thread Insert Free-State Structural Dimensions (Unit: mm)

| Nominal Diameter d | Pitch P | Outer Diameter in Free State Dz | Number of Locking Coils N2max | Number of Locking Edges K |

| d | P | Dz | ||

| 2 | 0.4 | 2.48~2.60 | 2 | 4~5 |

| 2.5 | 0.45 | 3.18~3.45 | 2 | 4~5 |

| 3 | 0.5 | 3.76~3.95 | 2 | 4~5 |

| 4 | 0.7 | 5.03~5.25 | 2 | 4~5 |

| 5 | 0.8 | 6.18~6.45 | 2 | 4~5 |

| 6 | 1 | 7.38~7.60 | 2.5 | 5~6 |

| 8 | 1.25 | 9.78~10.00 | 2.5 | 5~6 |

| 10 | 1.5 | 11.92~12.15 | 2.5 | 5~6 |

| 12 | 1.75 | 14.28~14.55 | 2.5 | 5~6 |

| 16 | 2 | 18.88~19.15 | 2.5 | 5~6 |

Note: The number of locking coils and the number of locking edges are only applicable to locking type wire thread inserts.

Φ —— Diameter of the selected drill bit;

L₁ —— Nominal diameter length of the tailless wire thread insert;

L₂ —— Actual length of the tailless wire thread insert after installation (L₂ = L₁ - P);

L₃ —— Drilling depth;

L₄ —— Thread depth of the internal threaded hole for installing the tailless wire thread insert (L₄ = L₁ = L₂ + P);

L₅ —— Distance from the tailless wire thread insert to the installation surface (L₅ = 0.25P ~ 0.75P).

| Nominal Diameter d | Pitch P | Nominal Length nd | L1 | Number of Coils N | L3 | L4 | L2 | L5 | Φ |

| 2 | 0.4 | 1d | 2 | 3.25 | 3.6 | 2 | 1.6 | 0.1 - 0.3 | 2.0 - 2.1 |

| 2 | 0.4 | 1.5d | 3 | 5.5 | 4.6 | 3 | 2.6 | 0.1 - 0.3 | 2.0 - 2.1 |

| 2 | 0.4 | 2d | 4 | 7.75 | 5.6 | 4 | 3.6 | 0.1 - 0.3 | 2.0 - 2.1 |

| 2.5 | 0.45 | 1d | 2.5 | 3.5 | 4.3 | 2.5 | 2.1 | 0.1 - 0.3 | 2.5 - 2.6 |

| 2.5 | 0.45 | 1.5d | 3.75 | 5.9 | 5.6 | 3.75 | 3.3 | 0.1 - 0.3 | 2.5 - 2.6 |

| 2.5 | 0.45 | 2d | 5 | 8.1 | 6.8 | 5 | 4.6 | 0.1 - 0.3 | 2.5 - 2.6 |

| 3 | 0.5 | 1d | 3 | 3.9 | 5 | 3 | 2.5 | 0.1 - 0.4 | 3.0 - 3.1 |

| 3 | 0.5 | 1.5d | 4.5 | 6.3 | 6.5 | 4.5 | 4 | 0.1 - 0.4 | 3.0 - 3.1 |

| 3 | 0.5 | 2d | 6 | 8.7 | 8 | 6 | 5.5 | 0.1 - 0.4 | 3.0 - 3.1 |

| 4 | 0.7 | 1d | 4 | 3.7 | 6.8 | 4 | 3.3 | 0.2 - 0.5 | 4.1 - 4.2 |

| 4 | 0.7 | 1.5d | 6 | 6.1 | 8.8 | 6 | 5.3 | 0.2 - 0.5 | 4.1 - 4.2 |

| 4 | 0.7 | 2d | 8 | 8.4 | 10.8 | 8 | 7.3 | 0.2 - 0.5 | 4.1 - 4.2 |

| 5 | 0.8 | 1d | 5 | 4.3 | 8.2 | 5 | 4.2 | 0.2 - 0.6 | 5.1 - 5.2 |

| 5 | 0.8 | 1.5d | 7.5 | 6.9 | 10.7 | 7.5 | 6.7 | 0.2 - 0.6 | 5.1 - 5.2 |

| 5 | 0.8 | 2d | 10 | 9.7 | 13.2 | 10 | 9.2 | 0.2 - 0.6 | 5.1 - 5.2 |

| 5 | 0.8 | 2.5d | 12.5 | 12.3 | 15.7 | 12.5 | 11.7 | 0.2 - 0.6 | 5.1 - 5.2 |

| 5 | 0.8 | 3d | 15 | 14.8 | 18.2 | 15 | 9.2 | 0.2 - 0.6 | 5.1 - 5.2 |

| 6 | 1 | 1d | 6 | 4.2 | 10 | 6 | 5 | 0.2 - 0.8 | 6.2 - 6.3 |

| 6 | 1 | 1.5d | 9 | 6.9 | 13 | 9 | 8 | 0.2 - 0.8 | 6.2 - 6.3 |

| 6 | 1 | 2d | 12 | 9.6 | 16 | 12 | 11 | 0.2 - 0.8 | 6.2 - 6.3 |

| 6 | 1 | 2.5d | 15 | 12.3 | 19 | 15 | 14 | 0.2 - 0.8 | 6.2 - 6.3 |

| 6 | 1 | 3d | 18 | 14.6 | 22 | 18 | 17 | 0.2 - 0.8 | 6.2 - 6.3 |

| 8 | 1.25 | 1d | 8 | 4.7 | 13 | 8 | 6.8 | 0.3 - 0.9 | 8.2 - 8.3 |

| 8 | 1.25 | 1.5d | 12 | 7.4 | 17 | 12 | 10.8 | 0.3 - 0.9 | 8.2 - 8.3 |

| 8 | 1.25 | 2d | 16 | 10.6 | 21 | 16 | 14.8 | 0.3 - 0.9 | 8.2 - 8.3 |

| 8 | 1.25 | 2.5d | 20 | 13.5 | 25 | 20 | 18.8 | 0.3 - 0.9 | 8.2 - 8.3 |

| 8 | 1.25 | 3d | 24 | 16.4 | 29 | 24 | 22.8 | 0.3 - 0.9 | 8.2 - 8.3 |

| 10 | 1.5 | 1d | 10 | 5 | 16 | 10 | 8.5 | 0.4 - 1.1 | 10.3 - 10.4 |

| 10 | 1.5 | 1.5d | 15 | 8.1 | 21 | 15 | 13.5 | 0.4 - 1.1 | 10.3 - 10.4 |

| 10 | 1.5 | 2d | 20 | 11.2 | 26 | 20 | 18.5 | 0.4 - 1.1 | 10.3 - 10.4 |

| 10 | 1.5 | 2.5d | 25 | 14.2 | 31 | 25 | 23.5 | 0.4 - 1.1 | 10.3 - 10.4 |

| 10 | 1.5 | 3d | 30 | 17.2 | 36 | 30 | 28.5 | 0.4 - 1.1 | 10.3 - 10.4 |

| 12 | 1.75 | 1d | 12 | 5.2 | 19 | 12 | 10.3 | 0.4 - 1.3 | 12.3 - 12.4 |

| 12 | 1.75 | 1.5d | 18 | 8.4 | 25 | 18 | 16.3 | 0.4 - 1.3 | 12.3 - 12.4 |

| 12 | 1.75 | 2d | 24 | 11.7 | 31 | 24 | 22.3 | 0.4 - 1.3 | 12.3 - 12.4 |

| 12 | 1.75 | 2.5d | 30 | 14.7 | 39 | 30 | 30.3 | 0.4 - 1.3 | 12.3 - 12.4 |

| 12 | 1.75 | 3d | 36 | 18 | 43 | 36 | 34.3 | 0.4 - 1.3 | 12.3 - 12.4 |

| 16 | 2 | 1d | 16 | 6.5 | 24 | 16 | 14 | 0.5 - 1.5 | 16.4 - 16.5 |

| 16 | 2 | 1.5d | 24 | 10.1 | 32 | 24 | 22 | 0.5 - 1.5 | 16.4 - 16.5 |

| 16 | 2 | 2d | 32 | 13.8 | 40 | 32 | 30 | 0.5 - 1.5 | 16.4 - 16.5 |

| 16 | 2 | 2.5d | 40 | 17.5 | 48 | 40 | 38 | 0.5 - 1.5 | 16.4 - 16.5 |

| 16 | 2 | 3d | 48 | 21 | 56 | 48 | 46 | 0.5 - 1.5 | 16.4 - 16.5 |

Thread Insert Production Process

Crafted with Skill·Made with Dedication — The Art of Precision Thread Insert Manufacturing

Please feel free to email us:arvin540@foxmail.com

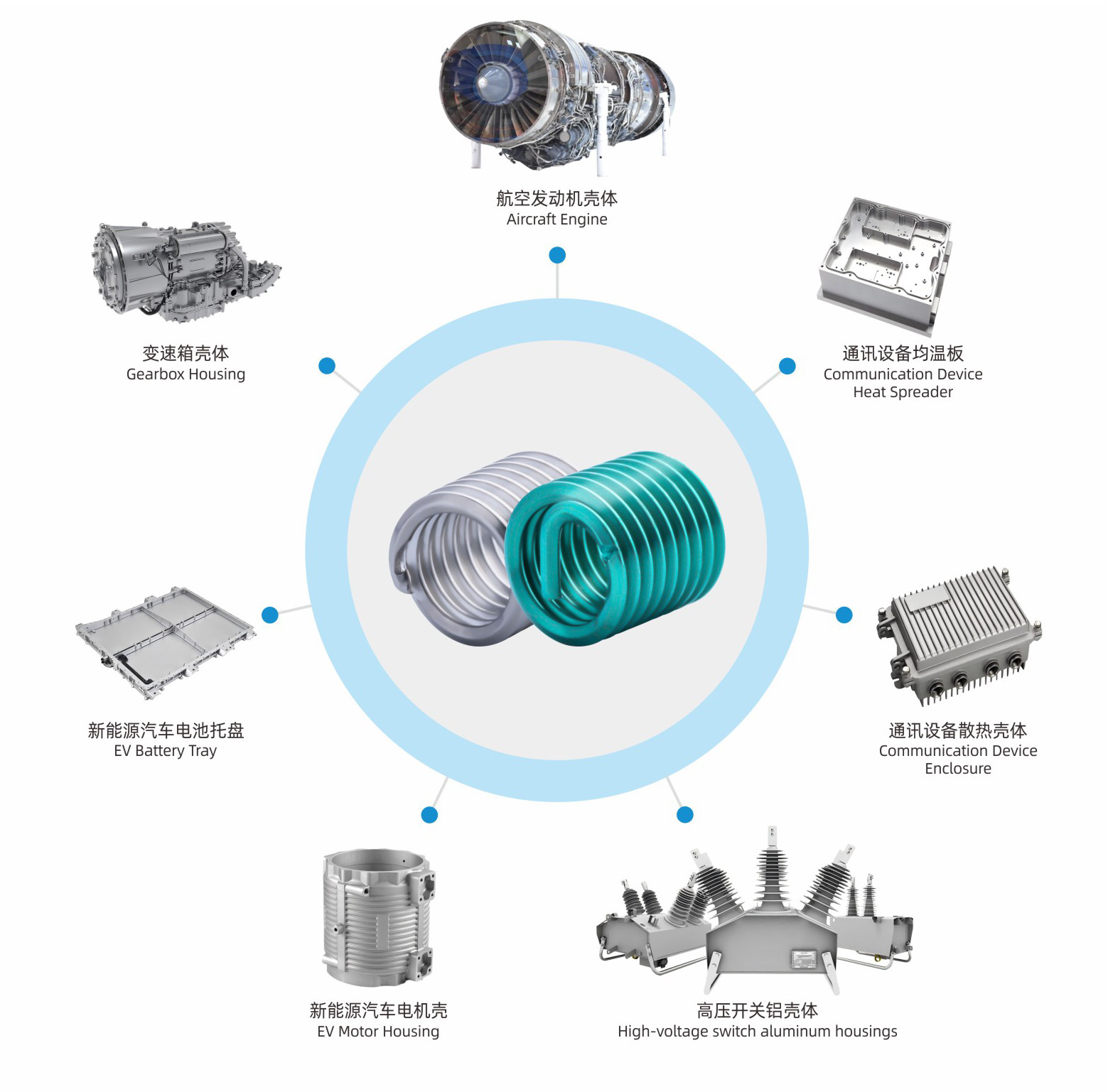

Industries Served

Industries Served

Typical Applications

Typical Applications

Helical inserts can be used in various threaded areas subject to high stress or wear. By enhancing thread strength and corrosion resistance, they significantly extend the service life of components.

Related Recommendations

Related Recommendations

Top

Follow us