Tang-Type Helical Inserts

Custom solutions available upon customer request

Tang-Type Helical Inserts

Custom solutions available upon customer request

Product Overview

Product Overview Standard wire thread inserts come in two types: one with a tang featuring a notch for break-off and one with a tang without a notch. They are made of multi-coil helical wire and, by selecting a proper installation length, form an elastic connection between the screw and the internal threads of the base material, eliminating thread manufacturing errors and increasing connection strength. Compared with traditional inserts, they reduce additional volume and weight.

Standard wire thread inserts with a break-off notch on the tang are mainly used in through-holes and are the most widely used type.

Standard wire thread inserts without a notch on the tang are mainly used in blind holes or deep holes where the screw end must not contact the installation tang after tightening.

Tang-Type Thread Insert Installation Tools

Taps for Wire Thread Inserts

Taps for wire thread inserts are used to machine special internal threads for wire thread insert installation holes. They are manufactured according to the national standard GB3464-83 (Straight-shank machine and hand taps) and are made of W6Mo5Cr4V2 high-speed steel. They can be used for both machine and manual tapping.

Straight-Flute Taps

Straight-flute taps have a wide range of applications and can be used for both through-holes and blind holes, as well as for ferrous and non-ferrous metals. Suitable for both hand and machine tapping and are relatively inexpensive. However, they are less specialized — short-lead taps are used for blind holes, and long-lead taps are used for through-holes.

Spiral-Flute Taps

Spiral-flute taps are more suitable for blind holes, especially when used with dedicated tapping machines or machining centers. Chips are expelled backward during tapping, resulting in high cutting efficiency and good surface quality of the internal threads.

Forming (Roll) Taps

Forming taps are ideal for machining tough non-ferrous metals, especially copper, aluminum alloy castings, and stainless steel. They produce internal threads through cold-forming, which yields high tensile and shear strength and better surface roughness.

Wire Thread Insert Installation Tools

Manual Installation Wrench

The basic principle is to guide the insert through a lead thread that compresses its outer diameter, allowing smooth insertion into the base hole.

Manual Tang Break-Off Tools / Automatic Tang Break-Off Tools

Tang Break-Off Tools: Break off the installation tang of wire thread inserts with a sharp impact.

Extraction Tools

Used to remove wire thread inserts installed in tapped holes.

Thread Plug Gauges for Wire Thread Inserts

Used to check the internal threads of the base holes prepared for wire thread inserts.

Product Parameters

Product Parameters Materials and Properties

Standard wire thread inserts are available in Unified Coarse (UNC), Unified Fine (UNF), and Metric thread sizes. The raw material can be 304H stainless steel, or other materials such as Nimonic 90 and phosphor bronze.

| Material | Grade | Service Temp | Tensile Strength at RT | Surface Condition |

| Stainless Steel | 304H;321 | 425°C short-term; 315°C long-term | >1400 MPa | No coating; Nickel-plated; Silver-plated |

| High-Temperature Alloy | Inconel X750; Nimonic 90 | 750°C short-term; 550°C long-term | >1400 MPa | No coating; Nickel-plated; Silver-plated |

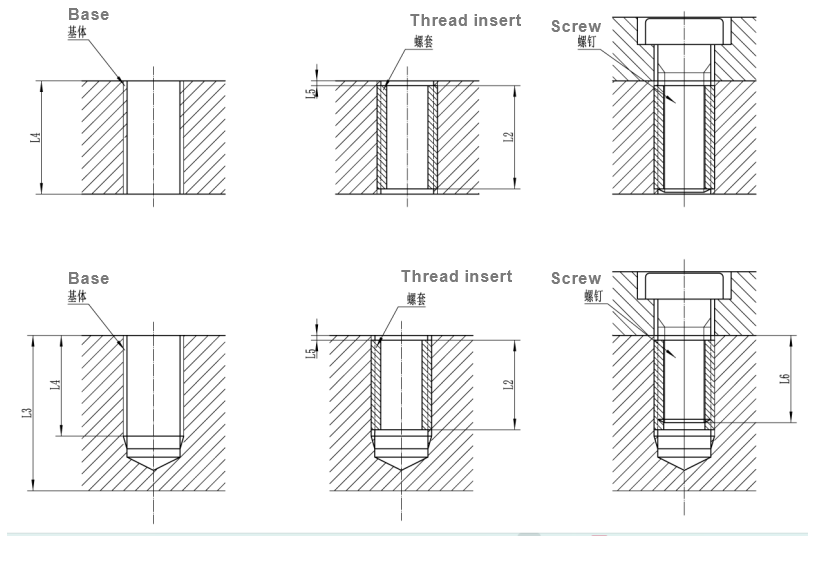

Selection of Nominal Length L of Wire Thread Inserts

The nominal length L of a wire thread insert, also known as the basic threaded hole length L2, is usually supplied as a multiple of the nominal thread diameter, i.e.: L2 = 0.5d; 0.75d; 1d; 1.25d; 1.5d; 2d; 2.5d; 3d …

The nominal thread diameter refers to the nominal diameter d of the screw that fits into the wire thread insert.

P:Pitch

W:Number of coils of the wire thread insert in free state

D:Nominal diameter of the wire thread insert (nominal screw diameter)

Dz:Outer diameter of the wire thread insert in free state

d0:Drill diameter selected for the hole

L1:Nominal length of the wire thread insert

L2:Actual length of the wire thread insert after installation

L3:Hole depth

L4:Thread depth of the tapped hole for installing the wire thread insert (same as L1)

L5:Distance from the wire thread insert to the mounting surface (L5 = 0.5P ± 0.25P)

L6:Maximum bolt insertion depth without removing the installation tang (same as L2)

Metric Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

![]() Metric Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

Metric Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

Coarse Unified Thread (UNC) Wire Thread Inserts-Types, Dimensions and Installation Parameters

![]() UNC Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

UNC Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

Unified Fine Thread (UNF) Wire Thread Inserts-Types, Dimensions and Installation Parameters

![]() UNF Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

UNF Series Wire Thread Inserts-Types, Dimensions and Installation Parameters

Thread Insert Production Process

Crafted with Skill·Made with Dedication — The Art of Precision Thread Insert Manufacturing

Please feel free to email us:arvin540@foxmail.com

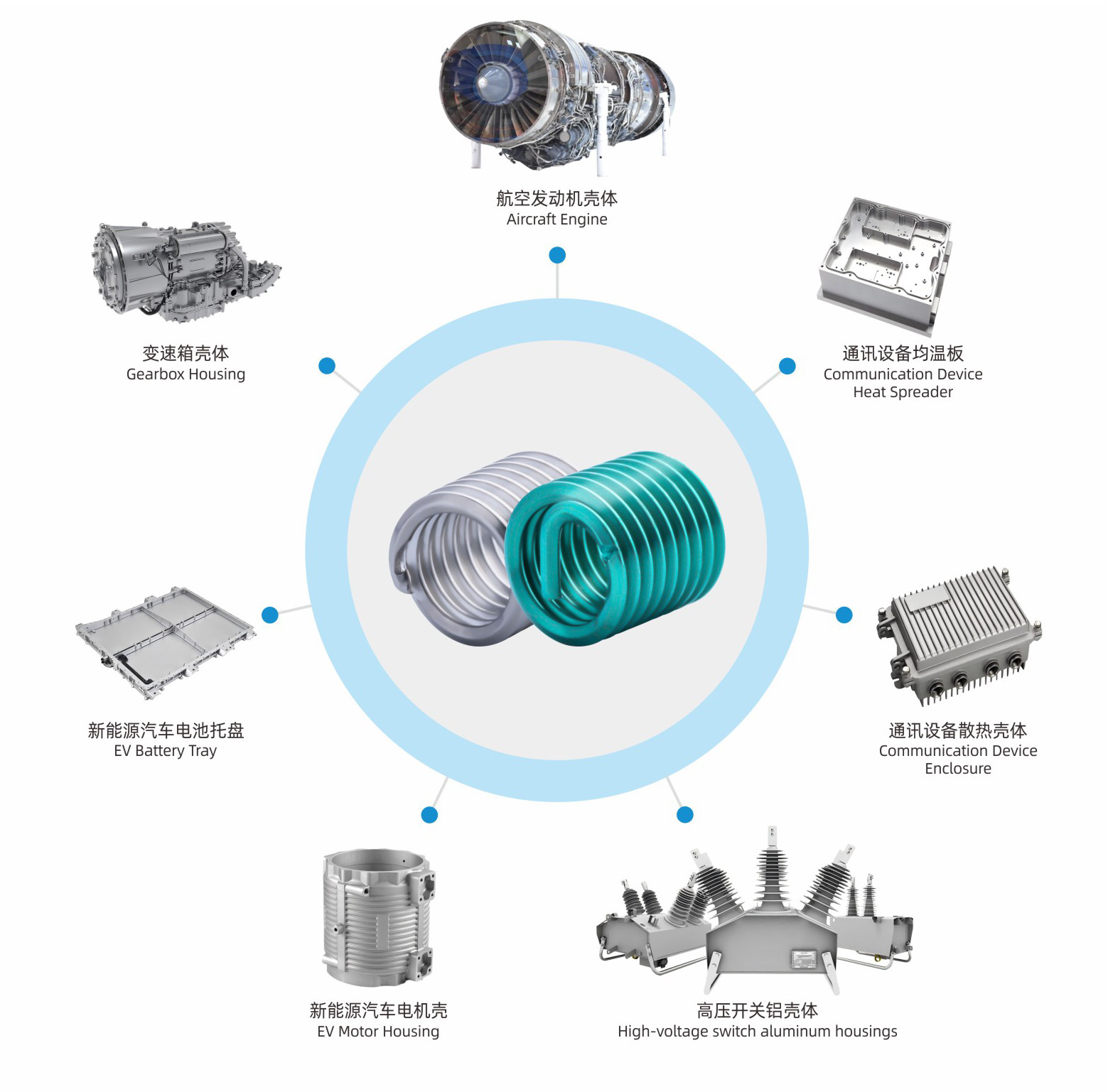

Industries Served

Industries Served

Typical Applications

Typical Applications

Helical inserts can be used in various threaded areas subject to high stress or wear. By enhancing thread strength and corrosion resistance, they significantly extend the service life of components.

Related Recommendations

Related Recommendations

Top

Follow us